Production Tracking

Maintenance, production, safety, quality, inspection, audits and much more procedures can be digitised with the new Augmented & Connected Worker solution.

What is a shutdown & turnaround?

Control of the produced parts, in order to provide useful information to analyze operation productivity, raw material needs, and stock, occupation time per equipment and person, decision making, among others.

Production tracking is considered as a specific action that may include a specific operator function that is trained to verify these needs. The worker monitors the productions, tracks the status of each operation, and may also be included in the quality of the production’s evaluation.

How is the Production Tracking implemented?

The tracking is usually carried out in paper registers or at a specific terminal in the production site, for example, in an excel file that will be furtherly transferred to other hierarchical levels for analysis. During the register, information about conformed and non-confirmed pieces is submitted, as well as data on the raw materials and components consumed by each one.

Additionally to the requirements demanded to each worker, a specific operator has a standardized process to follow. In this process, the worker must verify the overall production needs, on-the-making and inventory to verify ensure that production timings are following the patterns they should.

How the Connected Worker platform can improve the procedure?

Digital Work Instructions

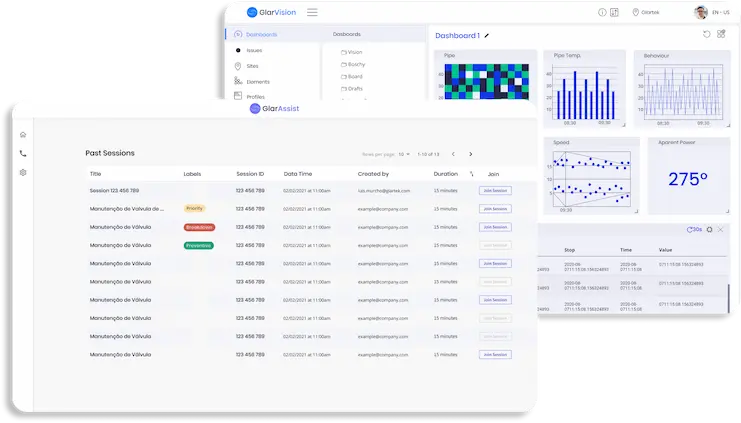

Product tracking can be done in real-time through the platform. By automatically collecting inputs from workers’ tasks completion, gathered with IoT data such as breakdowns, unexpected stops it is possible to monitor the production lifecycle in real-time.

Visual Inputs

Automatic reports are generated so data is displayed in a visual way that facilitate both comprehension and analysis. It becomes easier to understand where and why problems happened and take corrective measures

Benefits

Of going from Paper to Digital Procedures

More precise and with less error registers hence there is less time between execution and registration. In addition, in case of non conformity, decision-makers access information quickly.

- INCREASED PRECISION

- DECREASED ERROR

- PRODUCTIVITY INCREASE