Procedural Adherence

Maintenance, production, safety, quality, inspection, audits and much more procedures can be digitised with the new Augmented & Connected Worker solution.

What is a Procedural Adherence Process?

Procedural Adherence documents the employees’ compliance of the internal company processes and policies, such as the correct use of the Personal Protective Equipment, to ensure efficiency and safety of the personnel.

How is the Procedure Adherence implemented?

An Ad-hoc report is created to register compliances objectives to incentivize procedural adherence. Therefore, non-compliant behaviors are mitigated and reduced. The report typically identifies the employees, the procedure not respected, and any other relevant information.

Procedural Adherence starts with the idea that workers must respect pre-established steps to execute an operation.

But how can managers guarantee this compliant behavior?

- Write the steps of the procedure

- Train employees, so they can see the real benefit of following procedures

- Make the procedure document easy to access

- Reward compliant behaviors

How the Connected Worker platform can improve the procedure?

Digital Work Instructions

By digitizing the 4M Analysis process workers can access the information in real-time and help them in identifying the cause or causes of the problem.

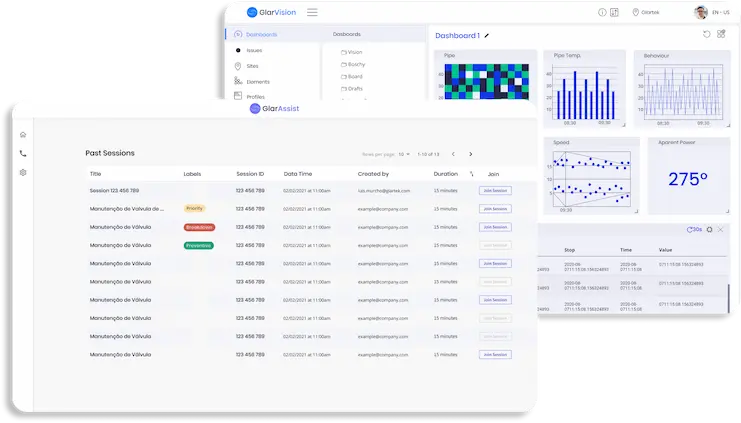

Automated Reports

Automatic reports are generated so data is displayed in a visual way that facilitates both comprehension and analysis. The report can identify the non-compliant employees, the procedure not respected, among other informations.

Benefits

Of going from Paper to Digital Procedures

With Industry 4.0 tools, knowledge retention is optimized and accelerated. Mobility makes the procedural adherence process more efficient and uniform. This reduces both error and the probability of putting workers or equipment in dangerous situations. Thus, the reports generated by this process can serve as base of data for future situations.

- KNOWLEDGE RETENTION

- AR MOBILITY

- AUTOMATED REPORTS

How can Glartek help?

Request your DEMO

It's time for you to join this New Reality

Start your Augmented & Connected Worker journey with us and become the leader of your industry.